Challenges Associated with Achieving Best CNC Machining Quality

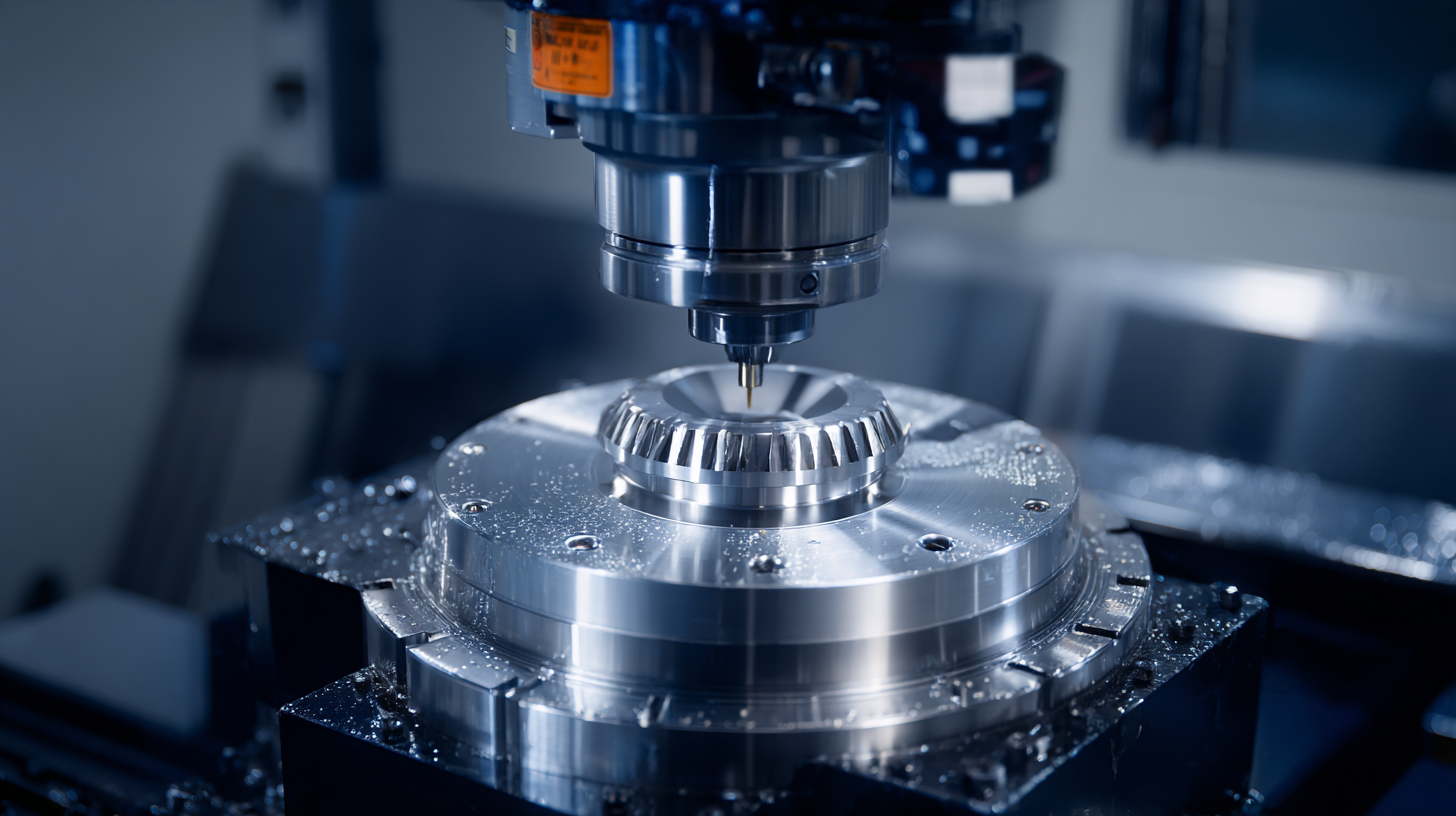

In the rapidly evolving landscape of manufacturing, achieving superior quality in CNC machining remains a significant challenge for industry professionals. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach $100.96 billion by 2025, highlighting the increasing reliance on these advanced technologies. However, ensuring precision and consistency in production can be hampered by various factors, including material selection, tool wear, and machine calibration.

A study conducted by the American Society of Mechanical Engineers (ASME) indicates that approximately 20-30% of production costs can be attributed to quality-related issues in CNC machining processes. This blog will explore the multifaceted challenges that manufacturers face in their pursuit of optimal CNC machining quality, comparing various approaches and techniques to overcome these obstacles effectively.

Challenges in CNC Machining Quality: An Overview of Industry Standards and Practices

CNC machining has revolutionized the manufacturing industry with its precision and efficiency, yet achieving consistent quality remains a challenge. Various industry standards and practices influence the machining process, shaping the way companies approach quality control. Factors such as material selection, machine calibration, and operator skill play a vital role in determining the final product quality. Adhering to recognized standards, such as ISO 9001, ensures that organizations maintain a structured approach to quality management, but implementation can be difficult.

To improve CNC machining quality, businesses should prioritize effective communication between departments. Aligning the engineering, production, and quality assurance teams can help identify potential issues early in the process. Regular training sessions for operators are essential, as they ensure that the workforce is up-to-date with the latest techniques and standards.

Another tip is to invest in advanced inspection technologies. Utilizing tools such as CMM (Coordinate Measuring Machines) can significantly enhance the accuracy of quality checks during production. Implementing real-time monitoring systems can also allow for immediate feedback, helping to catch discrepancies before they result in defective products. Embracing these practices can help organizations navigate the complexities of CNC machining quality.

The Impact of Tolerances and Precision: Navigating the Limits of CNC Machining

Achieving the highest quality in CNC machining is heavily influenced by tolerances and precision. Tolerances define the allowable limits of variation in a manufactured part, playing a crucial role in ensuring that components fit together perfectly within a larger assembly. When tolerances are set too tight, the risk of costly rework increases, as even minor deviations can render parts unusable. Conversely, overly lenient tolerances might compromise functionality, leading to performance failures or safety hazards. Thus, finding the right balance is crucial for optimizing machining processes.

Precision in CNC machining is equally significant, as it determines how accurately the machine can replicate designs. Advanced CNC machines are equipped with sophisticated technology that can maintain tight tolerances, but external factors such as tool wear, temperature fluctuations, and material inconsistencies can affect overall precision. Manufacturers must implement rigorous quality control measures and regular maintenance of equipment to mitigate these challenges. By navigating the limits of tolerances and precision, CNC machinists can enhance product quality and reliability, ultimately meeting customer expectations without overshooting production costs.

Challenges Associated with Achieving Best CNC Machining Quality - The Impact of Tolerances and Precision

| Aspect |

Description |

Impact on Quality |

Risk Level |

| Tolerances |

The allowable range of variation in a physical dimension. |

Directly affects fit and performance of machined parts. |

High |

| Precision |

The degree to which repeated measurements show the same result. |

Higher precision leads to better product reliability. |

Medium |

| Material Selection |

Choosing the right material for the intended use of the part. |

Influences durability and machining difficulty. |

Medium |

| Machine Calibration |

Ensuring CNC machines are properly set up and maintained. |

Direct impact on part accuracy and surface finish. |

High |

| Tool Wear |

Deterioration of cutting tools over time due to usage. |

Can lead to reduced accuracy and surface quality. |

High |

Material Selection and Its Role in Achieving Optimal CNC Machining Quality

Material selection is crucial in achieving optimal CNC machining quality, as it directly impacts the efficiency and effectiveness of the machining process. Different materials exhibit unique properties that influence cutting forces, tool wear, and overall machining performance. For instance, harder materials may require more robust tooling, which can affect feed rates and chip formation. This is essential, as improper material choice can lead to increased energy consumption, higher costs, and compromised product quality.

Furthermore, the influence of parameters such as the helix angle can significantly alter the dynamics of machining operations. For example, variations in helix angle affect cutting force and chip formation, which are critical to hole quality and tool longevity. Understanding these interactions allows for better predictions of feed forces, especially when employing machine learning algorithms to optimize machining conditions.

When designers and engineers prioritize material characteristics alongside machining parameters, they can enhance efficiency and ensure high-quality outputs in various CNC applications.

Technological Advances in CNC Machinery: Opportunities and Obstacles for Quality Control

The evolution of CNC (Computer Numerical Control) machinery has ushered in numerous technological advances that enhance manufacturing capabilities. However, these improvements also present significant challenges in maintaining quality control. As machines become more automated and complex, the potential for errors increases if not properly monitored. The integration of sophisticated software systems and advanced sensors can lead to intricate setups that may introduce new points of failure. Thus, while technology holds the promise of precision, it necessitates a vigilant approach to quality assurance.

Moreover, the rapid advancement of CNC technology often outpaces the ability of industry professionals to adapt to new changes. Operators and technicians must continuously update their skills and knowledge to effectively manage new machinery and software. Failure to do so can result in suboptimal performance and diminished product quality. Additionally, as companies strive to adopt cutting-edge CNC systems, the initial investment and ongoing maintenance costs can serve as obstacles to achieving desired quality levels. Balancing these elements is crucial for manufacturers seeking to leverage technological advancements while ensuring superior product quality.

Challenges in Achieving Best CNC Machining Quality

Quality Assurance in CNC Machining: Key Metrics and Industry Benchmarks to Consider

In the competitive landscape of CNC machining, maintaining high-quality standards is paramount.

Quality assurance plays a critical role in ensuring that every part produced meets industry specifications and customer expectations. To achieve this,

it is essential to focus on key metrics such as dimensional accuracy, surface finish,

and repeatability. Each of these metrics provides insight into the machining process, guiding manufacturers in identifying areas for improvement

and ensuring consistency in production.

Industry benchmarks also serve as valuable reference points for evaluating performance. By comparing their outcomes against these benchmarks, companies can assess their

quality assurance processes effectively. For instance, achieving a dimensional tolerance within ±0.01 mm

is a common standard in precision machining. Additionally, understanding the significance of surface roughness ratings helps in selecting appropriate tooling and machining strategies.

Manufacturers who prioritize these metrics and benchmarks not only enhance their product quality but also boost customer satisfaction

and loyalty.

Implementing robust quality assurance practices ultimately leads to sustained success in the ever-evolving CNC machining industry.