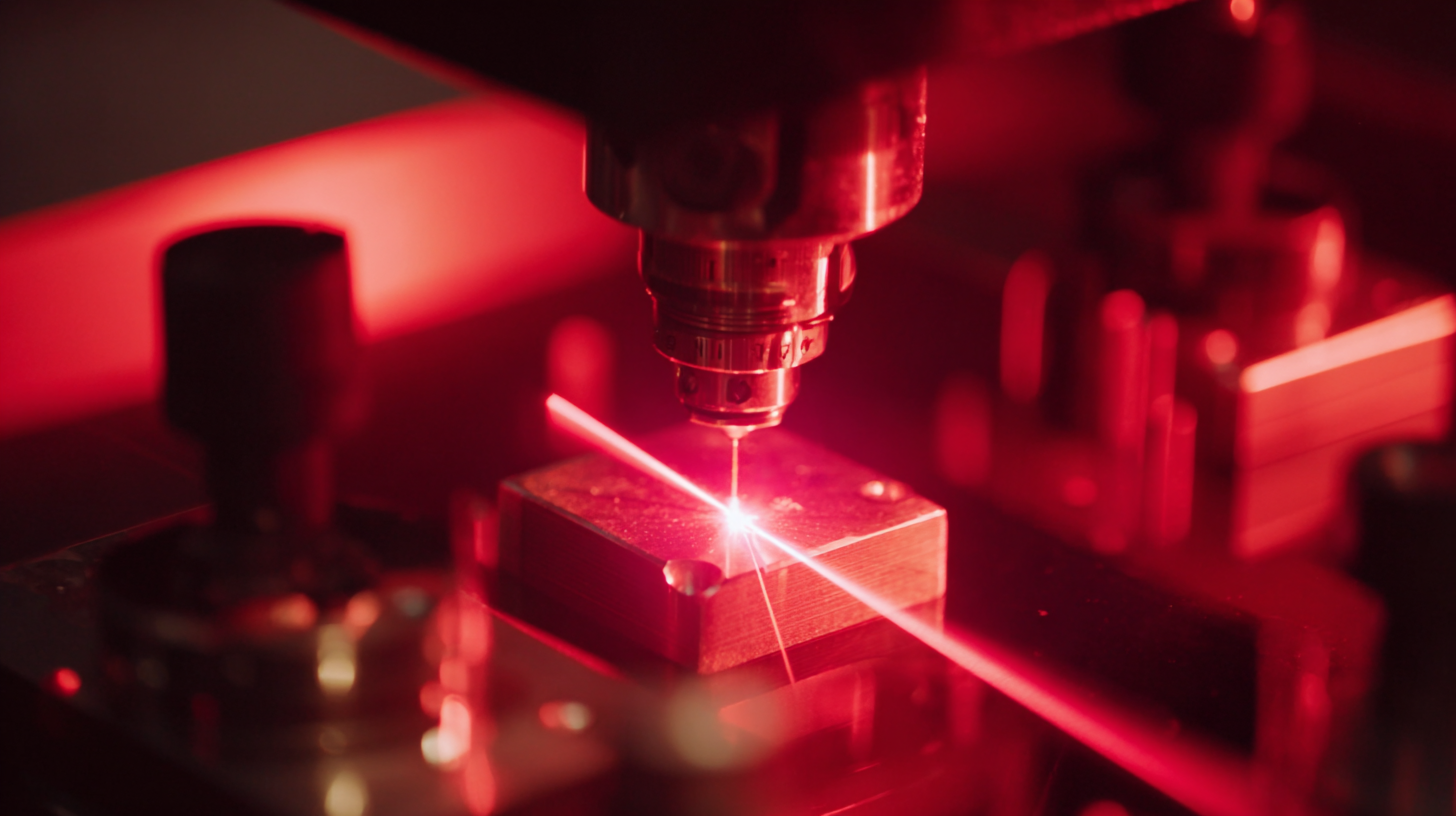

Unlock Precision: Discover the Best Laser Cutting Innovations from China’s Premier Manufacturing Facility

In the realm of modern manufacturing, precision is paramount, and laser cutting has emerged as a game-changing technology that revolutionizes how materials are processed. With its unparalleled accuracy and versatility, laser cutting offers exceptional solutions for a wide range of industries. As businesses seek to elevate their production capabilities, finding a high-quality manufacturer becomes crucial. This blog will guide you through the process of unlocking precision by discovering the best laser cutting innovations from China’s premier manufacturing facilities. We will explore key factors to consider when selecting a reliable partner, ensuring that your projects benefit from cutting-edge technology and impeccable craftsmanship. Join us as we delve into the world of laser cutting and how to optimize your manufacturing endeavors.

The Evolution of Laser Cutting Technology in China: A Comprehensive Overview

The evolution of laser cutting technology in China has marked a significant milestone in the global manufacturing landscape. With a focus on precision and efficiency, Chinese manufacturing facilities have developed state-of-the-art laser systems, exemplified by the recent launch of a 40,000-watt laser cutting machine. This breakthrough not only enhances cutting speed and quality but also demonstrates China's commitment to "specialized and innovative" small giants in the industry, which have become vital to strengthening supply chains amid global disruptions.

According to a report by the China Laser Industry Association, the laser cutting market in China is projected to grow at an annual rate of 15%, potentially reaching a value of USD 10 billion by 2025. This growth is fueled by advancements in technology that offer non-contact cutting capabilities, improved energy efficiency, and environmentally friendly operations. Laser cutting systems have been lauded as the "universal processing tool" of the future, integrating seamlessly into modern manufacturing ecosystems.

Moreover, strategic partnerships between domestic laser equipment manufacturers and logistics firms are paving the way for enhanced production capabilities. As seen in recent collaborations, these alliances bolster innovation and operational efficiency, positioning China as a formidable player in high-end manufacturing. Such developments underscore the nation's resilience in navigating external economic pressures, leveraging technological advancements as a hallmark of its continued industrial evolution.

Innovative Materials: How China's Laser Cutting Facilities Are Pushing Boundaries

China's laser cutting facilities are at the forefront of technological innovation, pushing the boundaries of what is possible with various materials. Engineered for precision and efficiency, these state-of-the-art manufacturing hubs are enabling the creation of intricate designs in metals, plastics, and even textiles. The advent of advanced laser technology, such as fiber lasers and CO2 lasers, has revolutionized the industry, allowing for smoother finishes and more complex cut patterns that were once thought impossible.

Moreover, these innovations are not just limited to traditional materials. Chinese manufacturers are experimenting with cutting-edge composites and lightweight alloys, expanding the scope of applications from aerospace to automotive industries. The ability to cut through thick materials with minimal distortion exemplifies the prowess of modern laser systems. As these facilities continue to integrate AI and automation, the industry anticipates further enhancements in production speed and accuracy, solidifying China's position as a global leader in laser cutting technologies.

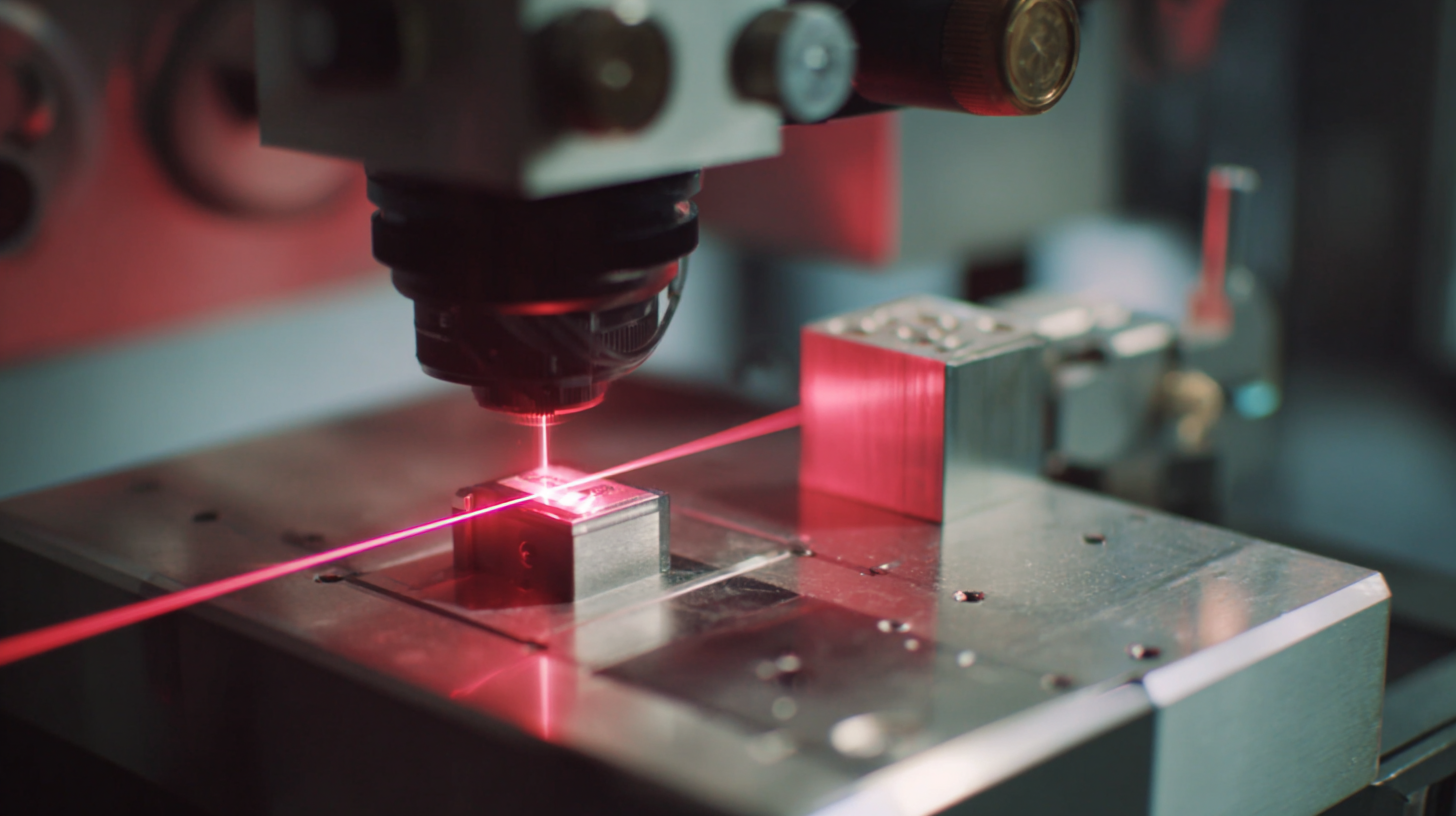

Precision Engineering: The Key Features of Top Laser Cutting Machines in China

In the rapidly evolving landscape of precision engineering, laser cutting technology stands out as a critical innovation in China's manufacturing sector. The advancements in laser cutting machines have revolutionized the way industries approach material processing. With features like high cutting speeds, exceptional accuracy, and the ability to handle a wide range of materials, these machines are essential for meeting the increasing demands of modern manufacturing. The integration of smart technologies and automation further enhances their capabilities, allowing for more efficient and precise operations.

Chinese manufacturers are at the forefront of producing cutting-edge laser cutting machines. The latest models boast powerful fiber laser systems, enabling operators to achieve intricate cuts with minimal waste. Notably, the robust build quality and premium components ensure longevity and reliability in high-paced production environments. As the global market for laser cutting machines is projected to surpass $12.65 billion by 2032, the continual innovation and focus on precision engineering will undoubtedly play a significant role in shaping the industry’s future.

Precision Engineering: Key Features of Top Laser Cutting Machines in China

This chart displays key features of top laser cutting machines manufactured in China, highlighting their speed, accuracy, maximum thickness capability, power output, and cost. These metrics are essential for assessing the performance and efficiency of modern laser cutting technology.

Sustainability and Efficiency: The Future of Laser Cutting in Manufacturing

The evolution of laser cutting technology in China's premier manufacturing facilities is a clear testament to the industry's commitment to sustainability and efficiency. Innovations in laser cutting not only enhance precision but also significantly reduce waste and energy use. By employing advanced materials and techniques, manufacturers are able to optimize the cutting process, ensuring that every beam of light is utilized effectively, minimizing scrap, and fostering a circular economy.

Moreover, the integration of eco-friendly practices into laser cutting operations reflects a broader trend towards sustainable manufacturing. Facilities are now investing in renewable energy sources, such as solar and wind power, to run their laser cutting machines. This commitment not only lowers the carbon footprint of production but also sets a benchmark for industries worldwide. As manufacturers harness the power of technology, they pave the way for a greener future, demonstrating that efficiency and environmental responsibility can coexist harmoniously.

Unlock Precision: Discover the Best Laser Cutting Innovations from China’s Premier Manufacturing Facility

| Innovation |

Efficiency Gain (%) |

Material Compatibility |

Sustainability Features |

Year of Introduction |

| High-Precision Fiber Laser |

30% |

Steel, Aluminum, Copper |

Reduced energy consumption |

2020 |

| Eco-Friendly Laser Cutting System |

25% |

Wood, Plastics |

Biodegradable lubricants |

2019 |

| Smart Laser Cutting Automation |

40% |

Metals, Composites |

Waste reduction through optimization |

2021 |

| Ultra-Fast Laser Technology |

50% |

Thin Metals, Glass |

Energy-efficient operation |

2022 |

Case Studies: Successful Applications of Laser Cutting Innovations from China

The advancements in laser cutting technology from China's premier manufacturing facilities exemplify a shift towards precision and efficiency across multiple industries. Notably, laser cutting innovations have been successfully integrated into the automotive and aerospace sectors, where components require intricate designs and the highest standards of quality. A recent report indicated that companies leveraging advanced laser cutting techniques achieve up to

30% reductions in material waste, showcasing the technology's impact on sustainable manufacturing practices.

Moreover, case studies reveal how these innovations are complemented by China's broader economic evolution. With its heightened focus on research and development, China has seen its universities and enterprises enhance their innovation capabilities significantly.

For instance, the electric vehicle sector, which is now producing two-thirds of the world’s EVs, heavily relies on precise laser cutting for battery casings and body panels—critical components that demand high reliability.

By examining these successful applications, it is clear that laser cutting technology not only drives economic growth but also sets new standards in production excellence within China’s advanced manufacturing landscape.